Front Loading Seal LF Series

is a Maintenance Dept Favorite

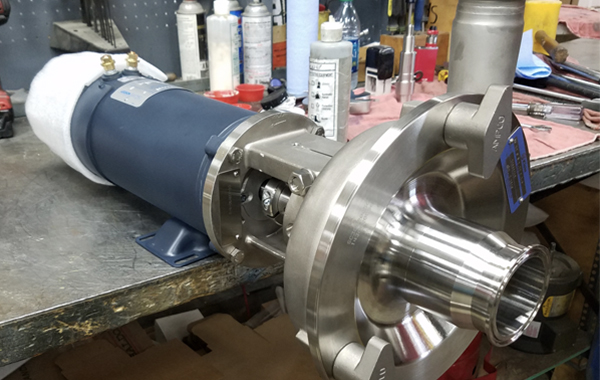

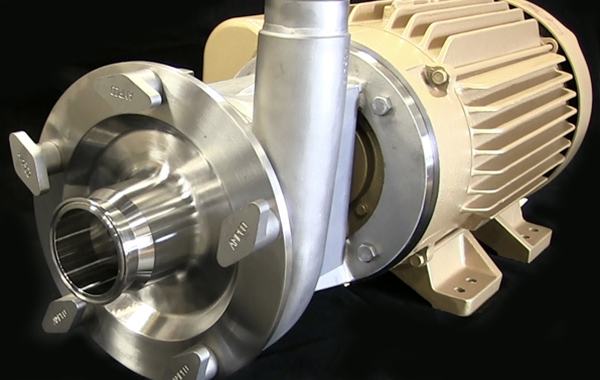

Ampco’s LF is designed with a unique front loading seal for maintenance ease and improved clean-ability.

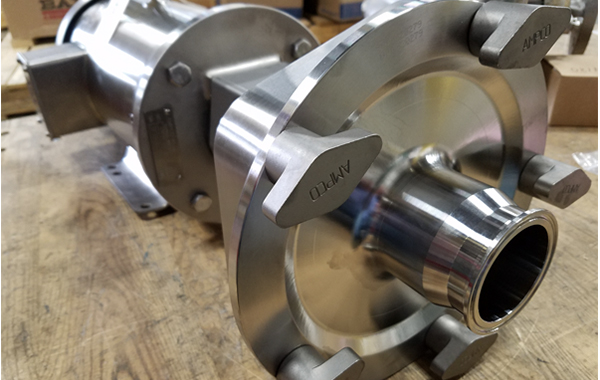

While seal designs in competitor pumps are known to leak due to product build-up when processing tacky or sticky products, the specially designed Ampco LF seal eliminates this problem area by removing the traditional O-ring groove and dead zone. The innovative design of the Ampco LF seal offers a semi-exposed O-ring allowing product to flow freely through previously restricted areas eliminating product build-up.

The LF seal design offers ease of assembly. Exclusive to the Ampco LF, the rotating seal stays retained in the driver during the assembly process too.

Balanced impellers, a self-aligning shaft design and tight manufacturing tolerances, minimize vibration and improve seal life, making the LF a preferred choice for difficult to handle products.

The LF Series is a highly efficient pump that gently handles product while providing a more sanitary seal design than competing pumps.

Industry leading delivery times, 304 stainless steel adaptors, seal design advantages, and a maintenance-friendly assembly process make Ampco’s LF Series a simple choice.

Cryogenic Low Temp Applications. CBD hemp oil or Cannabidiol is fast becoming a mainstream ingredient for beverages, health products, gels, and other consumables products. The extraction process of these valuable oils can require pumping ethanol at temperatures as low as -70F (-56C). Ampco has designed a special seal for positive displacement and centrifugal pumps that are suitable for these extremely low temperatures.

The LF Series centrifugal pump series with its internal seal design is a smart choice for this application providing durability, efficiency and tremendous maintenance advantages, contact Ampco’s Technical Sales Team today to discuss your specific application requirements.

Ampco Pumps LF Series Cryo-pump Technology – Learn More

Easy on maintenance the front loading seal can be changed simply by removing the front cover.

LF Series

Centrifugal Pump Features

- 316L Stainless Steel Heavy Wall Construction

- Cast and Machined

- 304 Stainless Steel Adapter

- Balanced Impellers

- 316L Stainless Steel Shaft

LF Series Performance Overview

Models: 13

Max Inlet Pressure: 150 PSI / 10 BAR

Max Flow Rate: 1800 GPM / 409 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 3 Seal Options

Proven Design & Upgraded Features

The LF Series gives end users the added benefit of a cleaner seal design with partially exposed O-rings making it easier to handle seal assembly. The result – reduced downtime resulting in greater profitability.

LF Series Centrifugal Pump Advantages

304 Stainless Steel Adapter

Cleaner Seal Design

Rotating Seal Retained for Ease of Assembly

Dimensionally and Hydraulically Interchangeable with Competing Pumps

Convert to Double Seal Easily in the Field

US orders: New pumps ship in 1-2 weeks, parts orders in 24 hours

International order transit times will vary based on destinationManufactured and Assembled in U.S.A.

The LF Series is a “drop-in” replacement for competitive or OEM sanitary centrifugal pumps – and offered at a highly attractive price point.

Available Models

| Model # | Curves | 1750 | 3500 | Data Sheet |

|---|---|---|---|---|

| LF R01/R02 | Curves | 1750 | 3500 | Data Sheet |

| LF R11/R12 | Curves | 1750 | 3500 | Data Sheet |

| LF R21/R22 | Curves | 1750 | 3500 | Data Sheet |

| LF R31 | Curves | 1750 | - | Data Sheet |

| LF R41/R42 | Curves | 1750 | 3500 | Data Sheet |

| LF R51/R52 | Curves | 1750 | 3500 | Data Sheet |

| LF R141/R142 | Curves | 1750 | 3500 | Data Sheet |

| LF V521/V522 | Curves | 1750 | 3500 | Data Sheet |

| LF V531/V532 | Curves | 1750 | 3500 | Data Sheet |

| LF V541/V542 | Curves | 1750 | 3500 | Data Sheet |

| LF V551/V552 | Curves | 1750 | 3500 | Data Sheet |

| LF X051 | Curves | 1750 | - | Data Sheet |

| LF X161 | Curves | 1750 | - | Data Sheet |

| LF V401 | Curves | 1750 | - | Data Sheet |