Choosing the Best Positive Displacement Pump for the Job at Hand

Not all pumps are created equal. The technologies available today are as varied as the applications, from food and beverage to personal care and beyond. The positive displacement (PD) pump market is full of options that can meet a wide range of performance capacities, pressures and viscosities. How do you know which positive displacement pump is the right fit for your needs? Our expert engineers have shared some insights on what to look for below.

Ampco takes the guesswork out of comparing PD pumps

The following is a high-level comparison designed to give you a closer look at the differences between lobe pumps, circumferential piston pumps and twin-screw pumps.

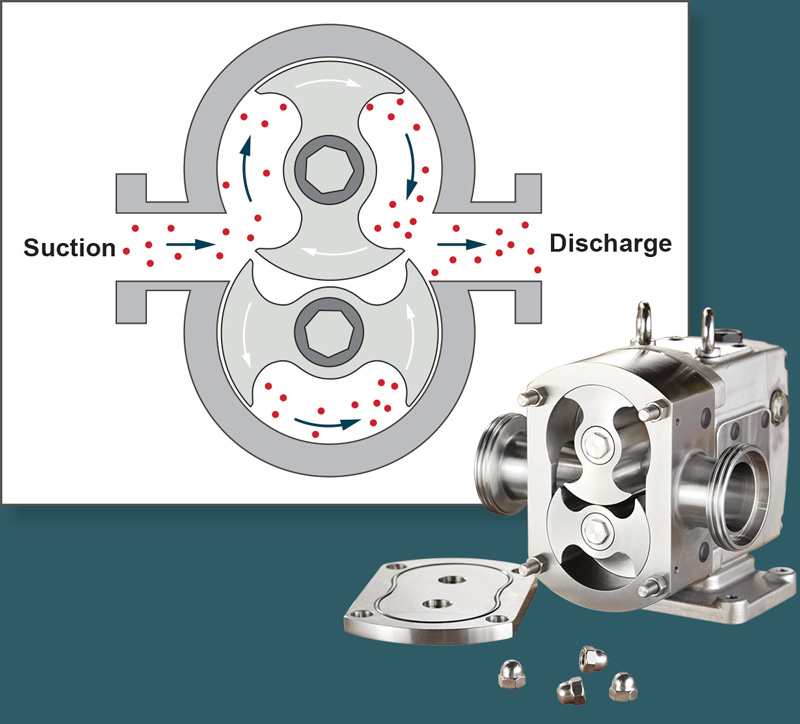

Rotary lobe pumps

Lobe pump rotors, like those in our AL Series, are in constant near-contact with one another but never drive each other like a gear pump. The rotors create a seal to transport product from the suction to the discharge side of the pump.

The AL Series is available in four different rotor wing options, including the single-, bi-, tri- and multi-lobe configurations. The varied rotor options allow for flexibility in performance and product handling. This design makes it an excellent pump for highly viscous products in the food and beverage, dairy and pharmaceutical industries.

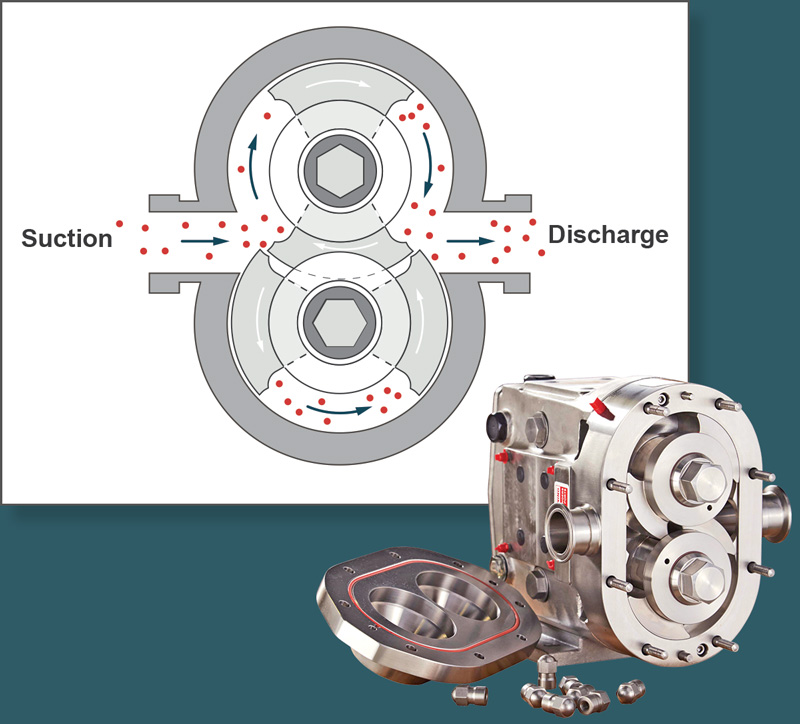

Circumferential piston pumps

Circumferential piston pump rotors, like those in our ZP Series, create the seal between stators that extend from the pump housing. The rotors also do not touch nor mesh. The sealing action only exists between the stators and rotors. Due to the additional geometric features, these pumps tend to be more expensive than lobe pumps. However, these features make circumferential piston pumps superior at low viscosity efficiency compared to lobe and twin-screw pumps.

Among other standard upgrades compared to competing pumps, Ampco’s ZP1+ and ZP3 series also offer a patented front-loading seal design that allows for faster and less-invasive seal changes.

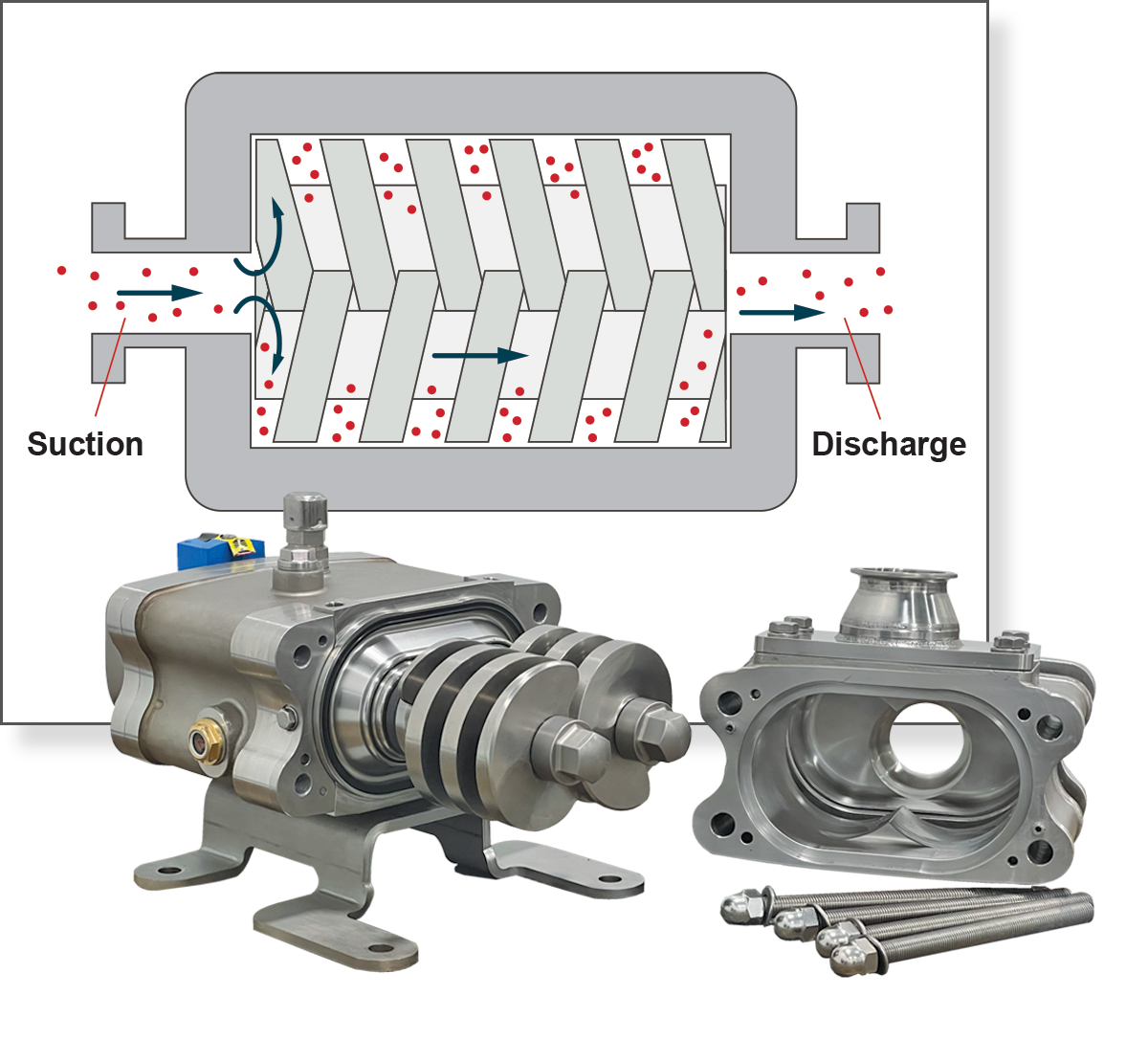

Twin-screw pumps

Twin-screw pumps, like our Bornemann SLH Series, are becoming more common among positive displacement pumps in food processing, pharmaceutical and industrial applications.

The two-spindle design displaces product in an axial direction. This pump type has very low pulsation, which reduces pump wear and aides in the gentle handling of product. Low pulsation also helps the twin-screw pump operate at higher RPMs. This gives it the advantage of being able to also function as a CIP supply pump, thereby simplifying piping and controls.

Twin-screw pumps are the most expensive option of these three PD pump types.

| Model | Type | CIP-able | High Pressure | Available Rotor Options | Front Loading Seal | Bidirectional Flow | High Speed |

|---|---|---|---|---|---|---|---|

| AL Series | Rotary Lobe |

√ |

√ |

√ |

√ |

||

| ZP1 Series | Circumferential Piston |

√ |

|||||

| ZP1+ Series | Circumferential Piston |

√ |

√ |

||||

| ZP2 Series | Circumferential Piston |

å |

√ |

√ |

|||

| ZP3 Series | Circumferential Piston |

√ |

√ |

√ |

√ |

||

| ZP4 Compact | Circumferential Piston |

å |

√ |

√ |

√ |

||

| SLH Series | Twin-screw |

√•• |

√ |

√ |

√ |

√ |

* only with modifications and adders

**dual duty pump / CIP return pump

Other things to consider when comparing PD pumps

When it requires pumping a product that is high viscosity, shear sensitive or contains entrained solids, our first recommendation in pump selection would be choosing a positive displacement pump that is the right fit for the application.

Not all pumps are created equal and the same holds true for pump manufacturers.

Things to look for in the company manufacturing your PD pump include:

- Front-loading seals and ease of maintenance

- Compliance with 3-A Sanitary Standards Inc. (3-A SSI)

- EHEDG (European Hygienic Equipment Design Group) certified

- The ability for pumps and parts to be easily interchangeable

- The lifetime of the pump and the service guarantee that comes with it

Sanitary Positive Displacement Pump Performance Curves:

Rotary Lobe Pump — (AL Series)

Performance Curves

Circumferential Piston Pump — (ZP Series)

Performance Curves

Twin-Screw Pump — (SLH Series)

Request Curve Information