Ampco Pumps Outperform in Demanding Applications

Marine and industrial applications are some of the most challenging environments Ampco products are applied. From harsh conditions and corrosive materials to end product quality demands, often the variety of logistical and physical considerations seem nearly insurmountable. Ampco embraces the challenge.

Ampco’s pumps are built to withstand the harshest environments over long periods of time. While corrosion and diminished functionality are major concerns for pumps handling saltwater, brackish water or wastewater, with Ampco, the concerns are mitigated.

Ampco’s product lineup starts with the best alloys and enhanced engineering designs to deliver maximum flexibility in application. The result – products that are corrosion resistant, efficient, reliable and durable.

Ampco’s experienced engineers can assist in choosing the best alloys and seal configurations to meet stringent application needs. Discover for yourself why Ampco customers choose to work alongside our engineers to ensure their Ampco pump selection is the right choice for performance excellence and product longevity.

Put Ampco’s decades of technical expertise and superior application knowledge to work for you. Contact Ampco today.

For nearly 75 years, Ampco Pumps has been exceeding industry expectations for demanding applications. Ampco’s marine and industrial centrifugal pumps go “above and beyond.”

Fastest Delivery of High Quality, Efficient Centrifugal Pumps

Best Selling Marine & Industrial Products

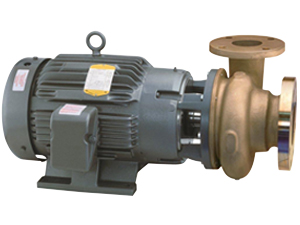

Z Series

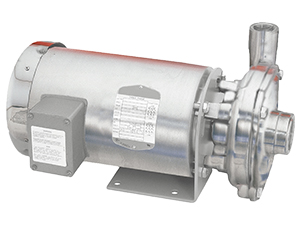

K Series

R Series

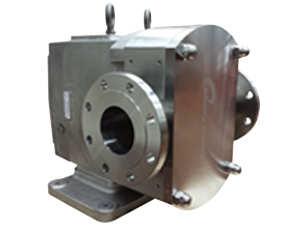

AL Industrial

Application Spotlight

Highland Engineering Inc., Howell, Michigan

“Ampco has been supplying the United States military and various Department of Defense contractors with durable and reliable pump technology since the 1940’s. A prime example is the Ampco KC2 pump used to boost pressure on a 1500 ROWPU reverse osmosis system. These systems, built by Highland Engineering, Inc., use Ampco pumps to stand up to brutal conditions around the world.”

Hardworking Pumps Deliver Performance and Longevity

Industrial Expertise

Ampco Pumps understands the variations and needs of the industrial market. It’s why we offer such a wide range of centrifugal pump series to fit distinctive and demanding conditions.

From Ampco’s R Series self-priming pumps up to 25+ feet below its base to the AL Industrial Series of high efficiency, rotary lobe pumps with their multiple rotor options, all Ampco pumps are superiorly engineered and remain very cost effective.

Ampco’s Z, K and R Series centrifugal pumps offer excellent product handling and excel in varying applications including clean water, wastewater, gray water and glycol. Each series delivers product performance longevity and corrosion resistance due to their robust designs and being manufactured from only quality materials with a wide range of alloy options.

Ampco’s industrial pumps are designed and ideal for applications, such as:

- Chemical Transfer

- HVAC Cooling Tower Water Circulation

- High Purity Wastewater Transfer

- Injection Molding Housing Cooling

- Ethanol and Diesel Fuel

- Hot Oil (Non-Food Grade)

- Semi Truck Wash Stations

- Wastewater Treatment (Effluent Side)

- Fire Suppression Foaming products

Marine Expertise

Ampco Pumps manufactures the most versatile centrifugal pump line for the marine market.

The Z Series is adaptable – from flush piping to special requests and government projects – and meets IEEE841 and other coast guard specifications. It’s heavy duty, as well, and comes in a wide variety of sizes and pressures to move a few gallons per minute to more than 3000 gallons per minute.

Ampco’s K Series is a smaller version of the Z series with more standard options.

Committed to producing best-in-industry centrifugal pumps for marine applications, Ampco produces pumps in a wide variety of alloy offerings. Customers can be ensured to find the correct pump in the right alloy for their specific need.

Ampco pumps are engineered for excellence and built to last. Specific marine applications include commercial saltwater applications, reverse osmosis, applications onboard marine vessels, engine and condenser cooling, refrigeration, fire pumps, effluent wastewater, and brackish water.

In fact, Ampco’s Z and K Series pumps are ideal for excellent outcomes of longevity in desalination.