BINEM Drum Unloading Systems Reduce Waste & Downtime, Increase Efficiency

Ampco Applied Products (AAP) has added the industry’s most innovative sanitary drum unloading system to our lineup of high-quality sanitary process equipment.

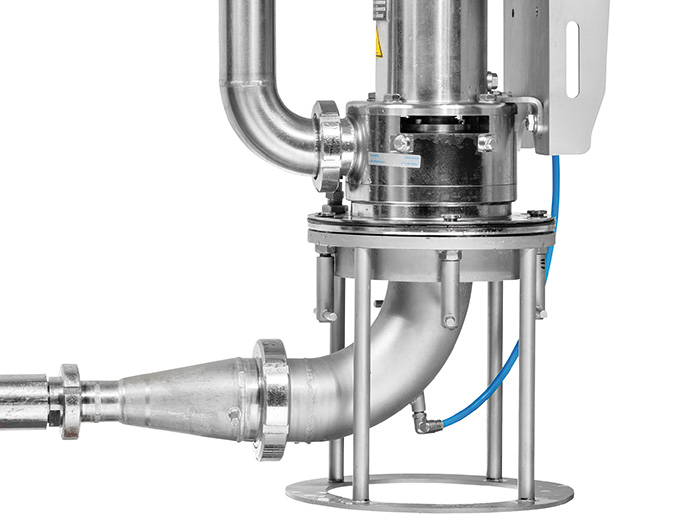

The BINEM Drum Unloading System was designed to maximize hygienic processing while reducing waste by utilizing a Bornemann twin screw pump. This technology delivers optimal performance and efficiencies compared to traditional air-operated drum unloading equipment.

Customizable dosing capabilities ensure consistency for every batch and safeguard remaining product from unsanitary exposure between uses. The BINEM Drum Unloading System easily pairs with control devices so you can pump in precise amounts of tomato paste, meat paste, chocolate spread, cookie filling, peanut butter and more.

Highly viscous products and those that are not self-leveling are perfect for the BINEM Drum Unloading System. This is due to the unique follower plate and inflatable rubber wiper design. Together, they deliver optimal performance and efficiency compared to traditional drum pumps and suction wands.

To make sure your lines remain up and running with minimal downtime, the BINEM Drum Unloading System is built for quick changeover. The one single pneumatic cylinder lifts the pump while a swing arm unit rapidly removes and replaces up to four drums per pallet. The lifting cylinder is also hygienically housed in the guiding system, and the follower plate can be effortlessly dismantled for quick and hygienic cleaning in place.

Speak with an AAP representative to learn more about how the BINEM Drum Unloading System can give your operations the Ampco Advantage.

Pump Unloading System

Standard Features

- Powered by a Bornemann twin screw pump

- Designed for highly vicious and not self-leveling products

- Multiple options for drum size/handling

- Pairs with control devices for batch dosing

- CIP-able

- Meets strict hygienic requirements

Specifications

Pressure: 362 PSI Max

Product Flow Rate: Up to 53 gpm

Viscosity: Up to 1,000,000 cP

Product Temperature: Max 212°F

Standard Features

CIP-Cleaning Module:

- Easier and more efficient cleaning and installation

- Can be used to empty bulk containers with low viscosity liquids

Follower Plate with Inflatable Wiper:

- Perfectly cleans drum sides for

less than 1% product waste - Secure seal keeps unused product sanitary between batches

Standard Controls:

Customizable Configurations

- Integrated Scale

- Drum Positioning Module

- Suction and Discharge Pressure Sensors

Drum Trolleys

- Pigging System

Easy to Use — Fits any Application

- More options — fewer limitations

Round or square, large or small, with or without a liner – BINEM Drum Unloading Systems are customizable to meet the unique needs of a wide variety of applications, including tomato paste, chocolate spread, fillings, peanut butter and many more. Batch dosing

The BINEM Drum Unloading System easily pairs with control devices, allowing precise amounts of product dosing.

Reduce waste and increase profits with BINEM Drum Unloading Systems from Ampco Pumps. Perfectly cleans drum sides for less than 1% product waste.

Available BINEM Models

| Model | Drum Size/Handling | Pump System |

|---|---|---|

| BINEM-200 | 55 gallon | 1 Pump |

| BINEM-1000 | 250 gallon totes or drums | 1 or 2 Pumps |