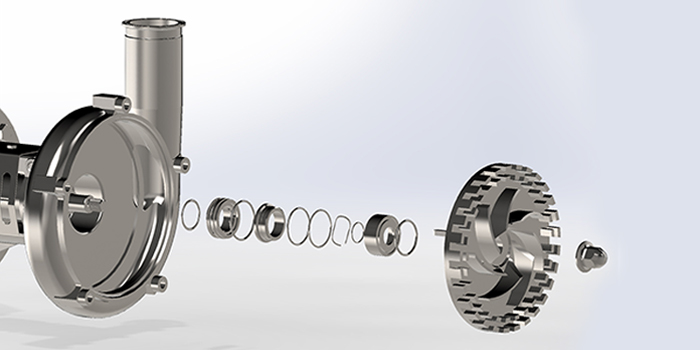

Performance Personified in SB/SBH/SBI Shear Blender Series

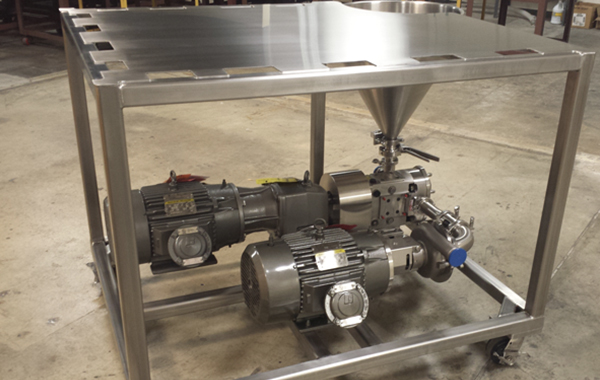

Ampco Applied Products’ offers 3 shear blender model series: SB/SBH/SBI. Applications range from pharmaceutical to food, industrial to chemical… and everything in between.

These are highly engineered products with critical tolerances machined, manufactured and assembled in Glendale, Wisconsin. Teeth thickness, number of teeth, radius and Cartesian coordinates of the SBI blades can all be customized. Contact the Ampco Applied Products application engineering team for full details.

All models can be customized upon request based on the specific application requirements.

SB Multi-Tasking Blender

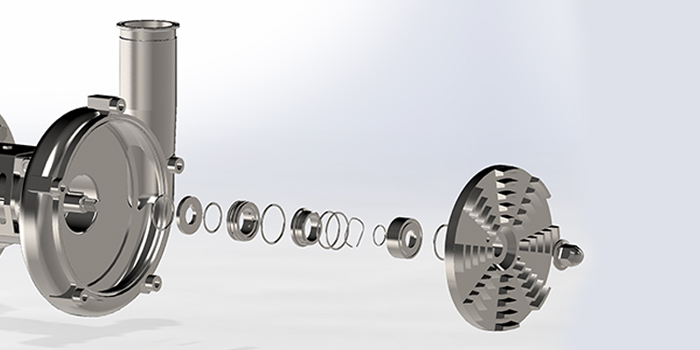

The SB Series is the most versatile blender available. This highly engineered blender is designed with trapezoidal shaped teeth that can be adjusted by the end-user. A set of shims, provided with the unit, gives users the ability to adjust the clearances between the static and dynamic teeth to create clearances as close as .030”.

The SB Series of blenders is based on the Ampco LF Series Pump line and offers multiple front loading seal options. Wet end parts are precision machined in house from 316L bar stock. The SB blender is best suited for shear sensitive applications.

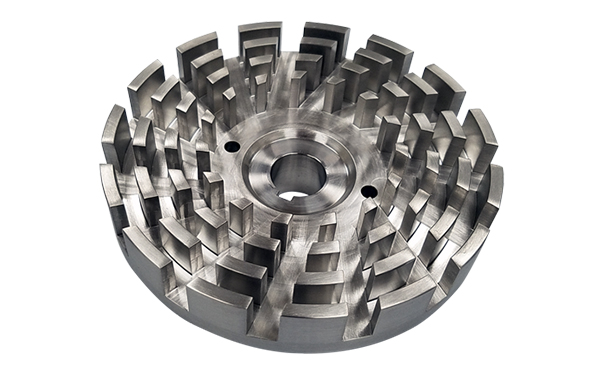

SBH High-Shear Blender

The high shear blending capability of the SBH is facilitated by the greater number and expanded rows of rectangular shaped teeth with radial slots for the highest shear possible.

Different cover and impeller sets are available for varying application requirements. The SBH Series, like the SB, is based on the LF Series pump design and offers multiple front loading seal options.

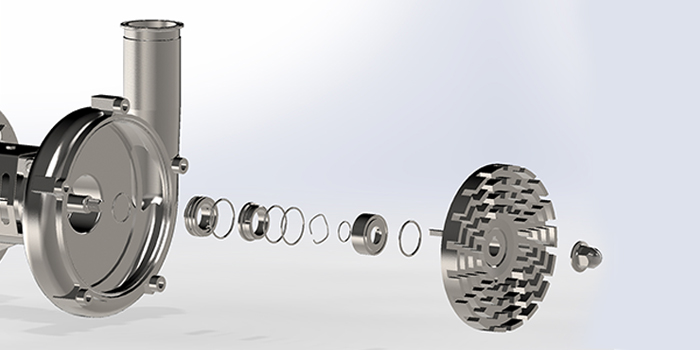

SBI Shear Pump

Pump and blend product in a single stage using the SBI Series. This innovative design can move product and create considerable pressure by way of a hybrid impeller.

This fine-tuned impeller design – used in combination with two rows of rectangular shear teeth – can attain amazing performance levels. As with the SB and SBH, the SBI is based on the Ampco LF Series pump and offers multiple front loading seal options.

SB Features

- Versatile, Adjustable Impeller Clearances – When Using Provided Shims

- 316L Stainless Steel Heavy Wall Construction

- Cast and Machined

- 304 Stainless Steel Adapter

- Dynamically Balanced Impeller

- 316L Stainless Steel Shaft

SB Performance Overview

Models: 4

Max Flow Rate: 200 GPM / 45 Mᵌ/hr

Seal Specifications: 3 Seal Options

SBH Features

- Highest Shear Levels

- 316L Stainless Steel Heavy Wall Construction

- Cast and Machined

- 304 Stainless Steel Adapter

- Dynamically Balanced Impeller

- 316L Stainless Steel Shaft

SBH Performance Overview

Models: 6

Max Flow Rate: 200 GPM / 45 Mᵌ/hr

Seal Specifications: 3 Seal Options

SBI Features

- Combination Integrated Impeller and Dynamic Shear Teeth

- Pump and Blend in a Single Stage

- Cast and Machined

- 304 Stainless Steel Adapter

- Dynamically Balanced Impeller

- 316L Stainless Steel Shaft

SBI Performance Overview

Models: 7

Max Flow Rate: 510 GPM / 116 Mᵌ/hr

Max Powder Induction Rate: 150 lbs/min / 68 kg/min

Seal Specifications: 3 Seal Options

Pumps in Action

“By using Ampco’s SBI Series blender, we got whole raw sweet potato pieces down to nearly 0% retention of a 0.023 screen in just one pass.”

Great Plains Food Processor

SB/SBH/SBI Advantages

- Customizable

- Front Loading Seal Options

- Easily Converted to Double Seal in the Field

- 304 Stainless Steel Adapter

- Affordably Priced

- Two Week Delivery

- Manufactured and Assembled in the U.S.A.