Cost Saving Advantages of Ampco’s Remanufacturing Program

Ampco’s remanufacturing program has earned an excellent reputation since introduced in 2010. This service will provide you with a completely remanufactured pump with all new internal components in just two weeks – guaranteed!

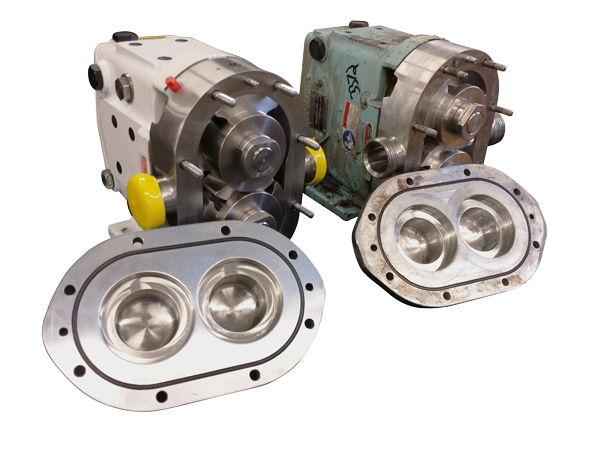

Ampco’s PD pump remanufacturing process includes new shafts, bearings, seals, helical style gears, new Alloy 88 rotors, and a one-year factory warranty.

Remanufacturing a used positive displacement pump is a significant cost saving alternative to purchasing a new pump, up to 30% less.

The Ampco remanufacturing program can even restore your SPX Flow / Waukesha Cherry Burrell Universal I and Universal II Series or Wright TRA10 and TRA20 style pumps (from 006 to the 520) to their original performance and efficiency.

Ampco ZP Series PD pumps offer complete interchangeability, superior parts quality, and reliability. Based on end user requirements, Ampco has remanufacturing services in two locations – Milwaukee, Wisconsin and Stockton, California.

Each completely remanufactured pump is performance tested and includes a full one-year factory warranty.

Remanufacturing Program Features

- Two Week Turnaround from Receipt of Purchase Order

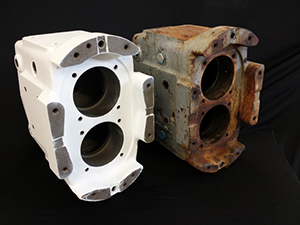

- Gearcase is Sandblasted and Powder Coated FDA White

- Pump Body and Cover are Re-Machined to Original Tolerances and Efficiency

- New Alloy 88 Rotors

Standard Upgrade Features – as with ALL NEW Ampco ZP Series pumps

- One Piece 17-4ph Shafts – More Than 3x the Yield Strength of 316

- Stainless Steel Bearing Retainers for Corrosion Resistance

- Stainless Steel Splash Guards to Protect Bearings from Water Intrusion

- Helical Gears for Greater Load Capacity and Quieter Operation

- Replaceable Threaded Grease Zerks

- Anti-Microbial Lube (Food Grade)

- Gasketed Stainless Steel Clean-out Plugs for Strength

- Completed Pump is Water Tested

Remanufacturing Process

Teardown - Step 1

Pump is completely torn down. All internal components; shafts, bearings, gears, spacers, and seals are removed and replaced with new components.

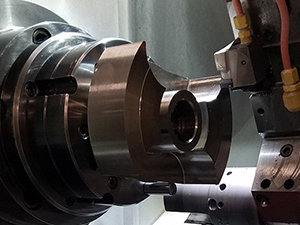

Machining - Step 2

Body and cover are machined to standard oversized dimensions + .020 / .040 / .060 / .080

Polishing - Step 3

The body and cover are polished back to their original 32 RA finish.

Rotors - Step 4

New oversized rotors are machined to bring tolerances back to match new pump performance / efficiency.

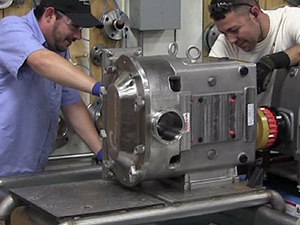

Assembly - Step 5

Pump is reassembled to factory specified tolerances of a new pump including seals and elastomers.

Testing - Step 6

Prior to shipment, pump is water tested to assure flow requirements and confirm seal integrity. Remanufactured pumps carry a one year warranty.

Remanufacturing Center Locations

Milwaukee Facility

4424 W Mitchell St. Milwaukee, WI 53214

414.643.1852 ext. 144 / 800.737.8671

Stockton Facility

1018 N Shaw Rd. Stockton, CA 95215

414.643.1852 ext. 160 / 800.737.8671