The ROLEC DH Provides Safe, Efficient Hop Induction

The ROLEC DH was developed by the Ampco Applied Products division with craft brewer needs in mind. This innovative product line offering was specifically designed to help the craft beer market meet its remarkable growth potential.

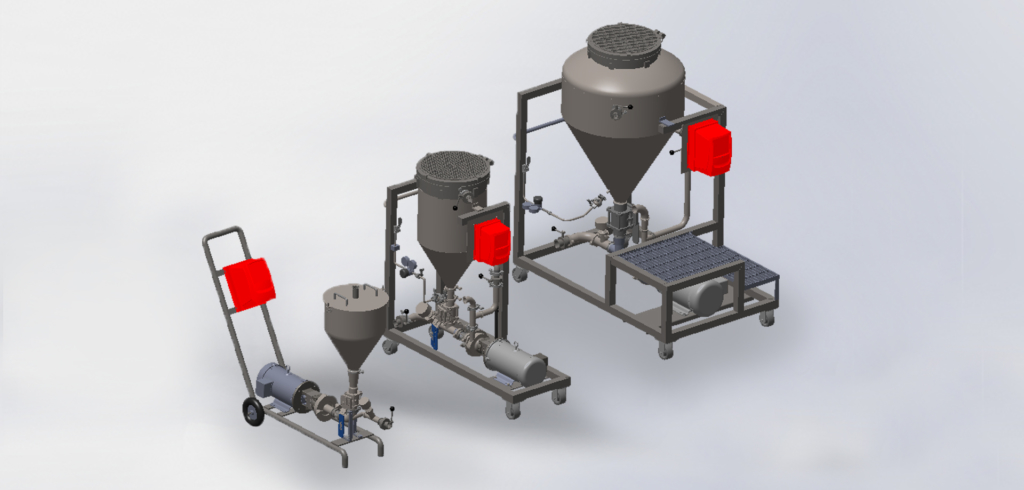

The ROLEC DH45, ROLEC DH90 and ROLEC DH250 models offer small to large scale breweries a safe and efficient way to dry hop and creatively induce flavors into beer.

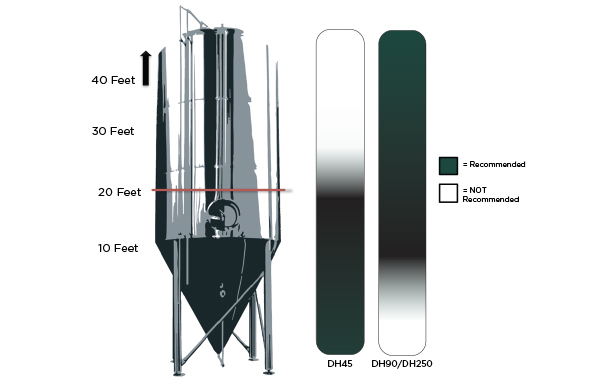

The ROLEC line eliminates breweries safety concerns of dry hopping on a ladder at the top of a two-story fermenting tank. These fully portable DH systems powered by Ampco’s in-line SBI shear blending pump are used at ground level.

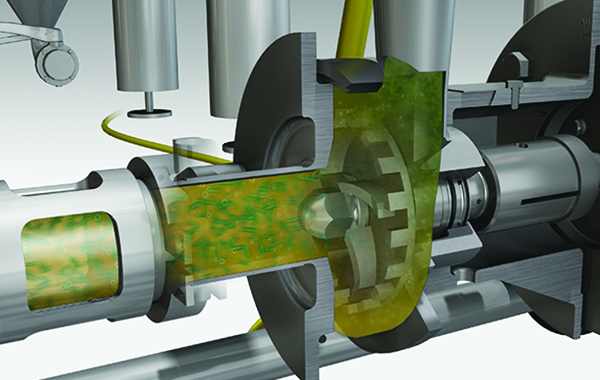

The SBI pump recirculates the fermenter while inducing dry hops and other induced media directly into the stream of beer; all from an oxygen free environment.

The DH90 and DH250 are built with a pressurized carbon dioxide chamber to mitigate oxygen intrusion. The DH45 is a smaller scale version offering a non-pressurized vessel utilizing a “blanket” of CO₂ to protect the product from oxygen intrusion. The DH45 is capable of induction on fermenters with a maximum height of 20 feet and can be used additionally as transfer and CIP pumps.

The ROLEC DH units are not just for hop induction, they can be utilized to induce fruit, coffee, spices, nuts, honey, maple syrup and more. The induction options are limited only by the brewers creativity.

Each Ampco Applied Products DH unit is delivered ready to go as a fully self-contained portable unit. VFD controls are in place. The sanitary DH90 and DH250 are CIP-able with no additional CIP pump required.

View Customer Testimonial Here – Lakefront Brewery Milwaukee, WI

The ROLEC dry hopping process maximizes pellet dispersion, flavor, and aroma. The increased surface area and forced contact produces dry hopped beer more efficiently than conventional methods – resulting in decreased tank-time and in many cases greater yield.

See How the Process Works

Other application opportunities include spices, coffee, lupulin biofine, fruit puree, sugar, cocoa nibs, and chocolate. Contact Ampco today to determine which model fits your brewery best.

Functional design under license of ROLEC PROZESS- UND BRAUTECHNIK GMBH, GERMANY, United States Patent no. 8,875,616

ROLEC DH Series

SBI Powered Dry Hop System Features

- 304 Stainless Steel Base Material

- 316L Wetted Parts

- All Models Include VFD (NEMA4X Standard)

- Stainless Steel / Polyurethane Casters

- DH45/ DH90 / DH250 are Fully CIP-Able with No Additional CIP Pump Required

- Standard 50’/15m Cord

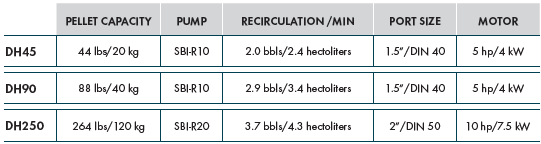

ROLEC DH Series Performance Overview

What the Brewers Say…

Ampco Applied Products’ ROLEC DH is being embraced around the world and are currently installed in breweries from New York to Australia.

“The AMPCO DH250 easily interfaces with our existing automation in place for our Mueller 725 bbl fermentation vessels, which has increased our breweries’ pellet brand capacity. Skid use is straightforward and safe, with a significant reduction in total time required for T90 pellet dosing as compared to our previous methodology. Sensory panel validation shows that dry hop quality with AMPCO use meets current brand standard, while GCMS indicates improved efficiency with higher levels of Myrcene and Linalool present in the final product.” – S.G. Assistant Brewmaster, Cellar – Deschutes Brewery

“With our graded floors, this unit made dry hopping much safer than with our scissor lift. We had a very noticeable increase in hop aroma from circulating with this unit too! Our DO sensor picked up no more O2 than normal.” – Midwest Craft Brewer

ROLEC DH Series Advantages

- Contains Everything Needed for Hop Induction

- Fully Portable

- Greater Hop Yield

- Improved Flavor and Aroma

- VFD Included

- Base Material 304 Stainless Steel

- Wetted Part 316L Stainless Steel

- Trials Available

- Manufactured and Assembled in U.S.A.

SBI-R00

Affordable Portable Fermenter Recirculation

The SBI-R00 is a unique and portable hop blending unit for fermenter recirculation with tremendous advantages over conventional cellar carts. Small scale brewers now have the ability to improve hop yield and increase surface area.

The SBI-R00 chops hop pellets while simultaneously recirculating the fermenter. The process uses a 1.5HP motor and VFD which can be operated using 115V single phase power.

Based on tremendous market response to the ROLEC DH 45/90/250 dry hop systems, the SBI-R00 was developed to make it possible for small batch brewers to enjoy many of the same benefits realized with the larger systems including decreased tank time, improved flavor profile and increased shelf life.

Contact the Ampco Applied Products team today to discuss how the SBI-R00 can benefit your brewery.

SBI-R00 Advantages

- 1.5 HP 3500 RPM Motor

- Available Voltages – 115V, 208V, 230V, 460V, 575V

- Up to 40 GPM / 9 m³/ hr or 1.3 bbls / min Recirculation Rate

- Up to 50 ft head / 22 psi / 1.5 BAR

- NEMA 4X VFD

- Input Cord Available

- Stainless Steel Two Wheel Cart

- Can Be Used as Cellar Pump

- Two Week Delivery

- Manufactured and Assembled in U.S.A.