AL Industrial Rotary Lobe Pump is Versatile

Take a proven design with tight manufacturing tolerances, offer multiple lobe styles and seal options, and you have the AL Industrial Series positive displacement pump.

Derived from the AL Sanitary Series, the AL Industrial Rotary Lobe Pump carries the same 3A and EHEDG Sanitary Certifications for hygienic applications.

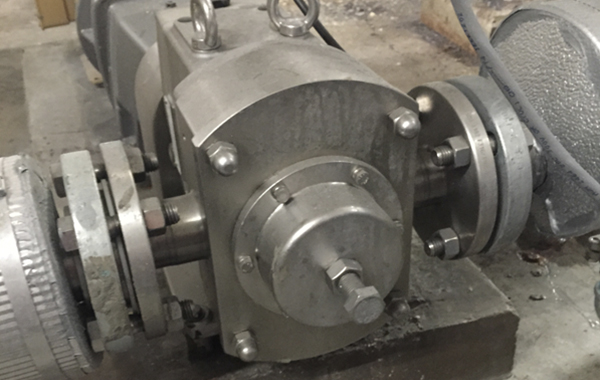

Embraced by the chemical industry, the AL is in processing applications around the world. The AL’s 316L stainless steel construction and non-contacting lobe design provide back-face tolerances as precise as .006”/.1524mm.

Low pulse pumping of shear sensitive products like dimethanolamnine and polyvinyl acetate is achieved through the variety of seals and lobe options.

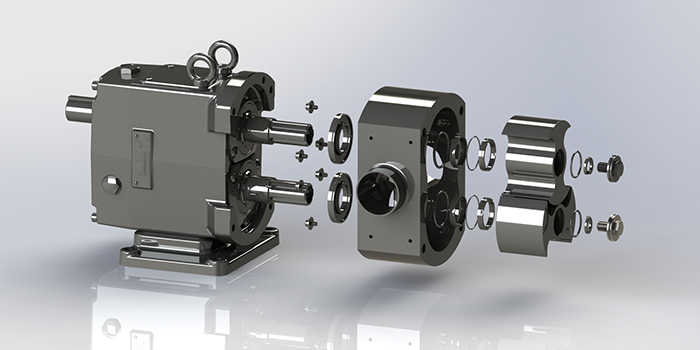

Multiple rotor designs are available including single wing, double wing, tri-lobe and multi-lobe. The standard rotor material is 316L stainless steel with optional Alloy 88 and Nitronic 60 available.

The AL Series offers 6 seal options including the double mechanical seal with flush ports to extend seal life and increase processing uptime. Contact Ampco’s application engineers today to discuss how the AL Series can fit your application requirements.

All AL Industrial Rotary Lobe Pumps come standard with a 304 stainless steel gearcase, 150# flange connections – predrilled for flush, and offer a front-loading seal design making them a maintenance department favorite.

AL Industrial Series

Rotary Lobe Positive Displacement Pump Features

- 304 Stainless Steel Gearcase

- Front-Loading Seal

- Cost Effective

- High Efficiency (Rotor Dependent)

- Multiple Rotor Styles – Single, Tri and Multi-Lobe, Single and Double Wing

- Multiple Rotor Alloys – 316L Stainless Steel, Alloy 88, Nitronic 60

- Multiple Seal Options – Single and Double Mechanical, Single and Double O-ring, Double Lip Seal

- Multiple Fitting Options – NPT, Cam and Groove, 150# Flange, DIN Flange, JIS Flange

AL Series Performance Overview

Models: 10

Max Discharge Pressure: 290 PSI / 20 BAR

Max Flow Rate: 440 GPM / 100 mᵌ/hr

Max Viscosity: 1,000,000 cP

Seal Specifications: 6 Seal Options

AL Series Positive Displacement (PD) Pump Advantages

- 304 Stainless Steel Gearcase

- Tight Manufacturing Tolerances

- Multiple Seal and Rotor Options Available

US orders: New pumps ship in 2-3 weeks, parts orders in 24 hours

International order transit times will vary based on destination- Manufactured and Assembled in the U.S.A.

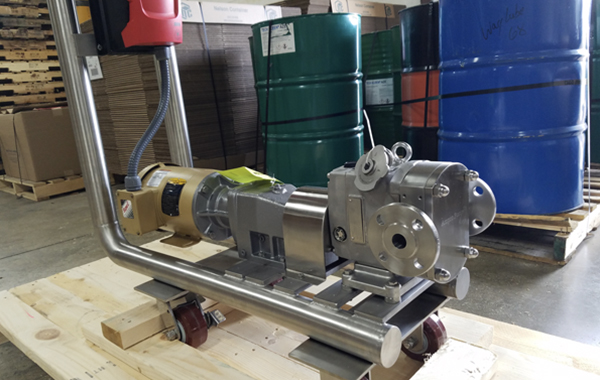

Pumps in Action

Heating jackets and pressure relief covers are available as options to further extend the list of applications and media types the AL can process. Other applications include paint, inks, dyes, glue, surfactants, epoxies, paper coatings, resins and more.

Available Models

| Model # | Curves |

|---|---|

| AL05 | AL05 Curves |

| AL10 | AL10 Curves |

| AL15 | AL15 Curves |

| AL20 | AL20 Curves |

| AL22 | AL22 Curves |

| AL25 | AL25 Curves |

| AL33 | AL33 Curves |

| AL34 | AL34 Curves |

| AL44 | AL44 Curves |

| AL46 | AL46 Curves |